Technical consultancy and training centred on all aspects of:

| design | specification | manufacture | validation. |

Fit, Form, Function (FFF) Review

In order to avoid problems in the later stage of a product development programme it is essential to validate the robustness of the manufacturing data before release.

There is anecdotal evidence that 1 week spent reviewing the data pays back 2 or 3 weeks after components are delivered.

Additionally, an independent review, with a fresh pair of eyes, is useful for confirming that:

• the plan is achievable

• costs are justified

• risks have been identified

• contingency plans put in place

Finally there are other benefits, albeit on a less tangible level. The act of conducting a review encourages the design team to bond, gain credibility, share knowledge and experience thus making it stronger and better able to face the challenges of the next task.

more details

specimen document

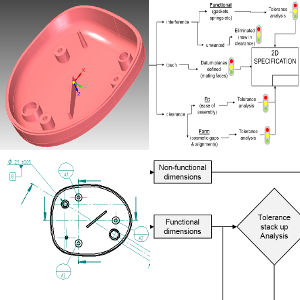

Tolerance Analysis Training

The analysis of tolerance stack-ups is an essential component of good product design.

Variation will always be present in any manufactured product and the accumulation of these small variations can have a devastating effect on profitability and reputation.

While there is no official standard covering the analysis of tolerances, this course recommends an approach which can be adopted to identify and prioritise the critical tolerances that govern the fit, form and function of the product.

After completing the course candidates will be able to use tolerance analysis as an everyday part of mechanical design. Enabling it to be used as a predictive tool and not as an ‘after the event’ problem solving one.

more details

specimen template

Consultancy Service

Providing expert, professional advice for the OEM and Contract Manufacturing sectors alike, from concept through to delivery.

Having worked on ‘both sides of the fence’ IMCE is well placed to understand the needs of both sectors, offering practical help and support based on over 37 years of experience. From the use of GD&T through to DFA/M, SPC/Cpk and ISIR/FAIR.

Whatever your needs, IMCE can offer solutions to the recurring problems of:

• Cost Reduction

• Time Reduction

• Revenue Optimisation

• Warranty Impact Reduction

• Risk to Loss of Repeat Business

more details

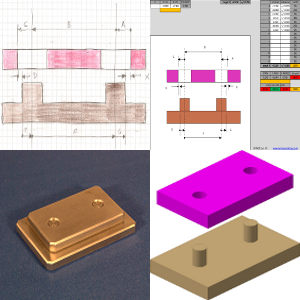

‘Partially’ Dimensioned Drawings

Before the advent of affordable 3D CAD, design engineers used to produce fully dimensioned 2D drawings.

In the 21st century it is now possible to produce ‘partially’ dimensioned drawings which rely on the interrogation of the 3D CAD to provide the ‘unspecified’ dimensions.

This delivers advantages in the reduction of drawing creation time and a corresponding reduction in inspection time.

However this strategy is not without risks. Done incorrectly, the final specification is less contractually robust leaving the company exposed to greater risk, especially in the case of a dispute.

This training course provides a method of producing partially dimensioned drawings which are clearer, more concise, quicker to produce, quicker to inspect and yet contractually robust in event of a dispute.

more details

FMEA Facilitation

Do you find conducting an FMEA to be difficult and time consuming?

Are you always arguing over which scores to use?

Perhaps you’re not sure where to start or even when to finish.

Are you concerned that the process doesn’t deliver the benefits that you hoped it would.

IMCE can offer to facilitate a ‘lean’ FMEA for you. Quicker, more focused than an old style FMEA but delivering the same prioritised list of risks and actions.

more details